When picking the right motor for air systems like compressors, people often choose between two main types: Permanent Magnet Synchronous Motors (PMSMs) and Induction Motors. Knowing how these motors are different can change how well your equipment works. It affects things like saving energy, how much fixing it needs, and how long it lasts. This guide looks closely at how PMSMs and Induction Motors do in air systems. We will see their good points and bad points. We will also give useful tips for picking the best motor for your job.

In this article, we will check the tech differences between PMSMs and Induction Motors. We will talk about how well they use energy. We will see how they act when loads change. We will look at how they save space. And we will see how much care they need in air systems. By the end, you will know more about each motor type. You can see which one fits your work. This helps if you want to save power or make fixing easy.

The big difference between PMSMs and Induction Motors is in how they are built. It is also in how they make turning force.

PMSMs use magnets that are always there. These magnets make a steady magnetic field. This makes PMSMs better at saving energy in some jobs. They are good when you need exact control. People use them a lot in air systems like compressors. Here, steady power is important.

On the other hand, Induction Motors use electric fields to make turning force. They need changing current to create a spinning field. Induction Motors have been used for a long time. But they often need more fixing. They are less good at saving energy than PMSMs. This is true when speeds change a lot.

PMSMs are made to change energy very well. This makes them very efficient. In air systems like compressors, the magnets give a steady field. This cuts energy loss, even at slow speeds. This good efficiency means less power used. It saves money over time. For example, in PMSM vs Induction Motor for air compressors, PMSMs usually eat up less electricity for the same job. This lowers running costs.

Induction Motors work well in many cases. But they are not as efficient as PMSMs most times. This is worse when loads vary. Energy loss is higher in Induction Motors. This happens because they use electric fields. It causes heat and more wear over time. So, air systems with Induction Motors can cost more to run later on.

PMSMs give exact speed control and steady turning force. This makes them perfect for air systems needing regular work. You can change the motor speed finely. This leads to better operation. It helps when air pressures or loads shift. For example, in air compressors, PMSMs can adjust speed fast when loads change. This drops energy use. It also makes the whole system more stable.

A big plus for PMSMs is less fixing. They have fewer parts that move. And they have no brushes. So, PMSMs wear down less over time. This means lower fixing costs. It also means they last longer. This makes them a top pick for air systems that run all the time.

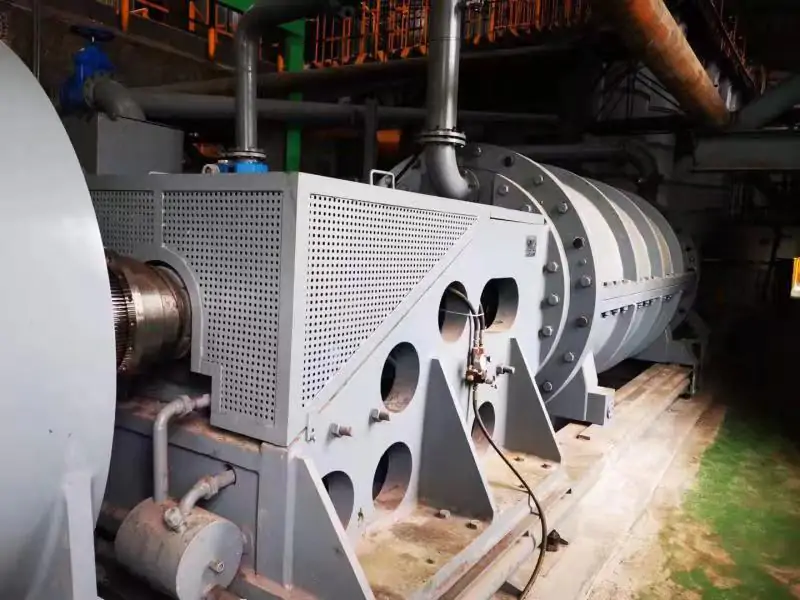

PMSMs are smaller than old-style Induction Motors. This is because they do not need extra parts like brushes or slip rings. So, they are great for tight spots. Whether it is a small factory corner or a tiny air compressor, PMSMs can fit. Induction Motors might not. This makes PMSMs more handy in today’s air systems.

In air compressor systems, saving energy is key. PMSMs are built to cut energy loss. So, they boost how well compressors work.

PMSMs use magnets to make a magnetic field. So, they need less power than Induction Motors. This lets air compressors work better. It is good when you need changing air flow.

Enhanced Torque and Stable Operation

PMSMs give steady turning force, even if loads change. This is vital for air compressors. Here, constant air flow is a must. The steady work of PMSMs means less pressure jumps. This lowers the chance of problems or bad work.

You can read more about the specific PMSM motor advantages and disadvantages for air compressors and how they make things better.

PMSMs need little fixing. They have no brushes and less rubbing parts. In air compressors, systems often run non-stop. Less wear means fewer breaks and less service. Usually, just cleaning now and then and adding oil keeps them going well.

But Induction Motors in air systems need more care. This includes checking bearings and windings. You might have to replace brushes. Over time, this can cost more for service. It can also cause downtime. This is bad in factories where air compressors are key. You can find more details about air compressor PMSM maintenance and why regular care is key for long life.

PMSMs save a lot of space over Induction Motors. They are smaller and have no big parts like gearboxes or fans. This makes them easy to put in tight spots. For example, in air compressor units, PMSMs can fit in small boxes. This frees up room and shrinks the gear size.

Old Induction Motors often need extra parts. These include gearboxes or coolers. This takes more space and makes things messy. PMSMs, though, work well without these. So, setting them up is simple. It keeps the layout neat.

Picking between a PMSM and an Induction Motor for air systems depends on a few things. Think about saving energy, fixing needs, and size. PMSMs are better at using power. They cost less to fix. And they are small. This makes them ideal for new air compressors and HVAC systems. Induction Motors are cheaper for some jobs. But PMSMs are best for air systems that want good work for a long time. They offer exact control and save money.

ENNENG specializes in the design and manufacture of high-performance industrial motors tailored for demanding applications. The company focuses on delivering durable, energy-efficient motors for industries like air systems, water pumps, and more. Known for its innovative approach, ENNENG ensures that its products help customers improve operational efficiency and reduce energy consumption. With a commitment to quality and reliability, their motors are built to provide consistent performance and meet the evolving needs of modern industries.

Q1: What makes a PMSM ideal for air compressor systems?

A: PMSMs are very efficient. They give exact speed control and steady turning force. This keeps air flow regular and uses less power in air compressors.

Q2: How does the maintenance of a PMSM compare to an induction motor in air systems?

A: PMSMs need less fixing. They have no brushes and fewer moving parts. So, long-term costs are lower than for induction motors.

Q3: Can PMSMs handle variable loads in air systems?

A: Yes, PMSMs are great with changing loads. They give steady force and work well in all conditions.

Q4: What are the key benefits of using PMSMs in air systems?

A: The big benefits are better energy use, lower fixing costs, a smaller size, and good control with load changes.

Q5: Why are PMSMs more space-efficient than induction motors?

A: PMSMs are smaller. They do not need extra parts like gearboxes or fans. This makes them good for tight spots. Also, think about why choose synchronous motors for compressor systems—they offer similar space savings and efficiency.