Choosing an electric vehicle drive motor is not just picking a motor type. It is choosing how your vehicle will behave under real load, heat, and repeated starts. For many platforms, PMSM (a permanent magnet synchronous motor) has become the default option because it can deliver strong torque, good control, and high EV motor efficiency across a wide speed range. But PMSM is not “perfect everywhere.” Its benefits show up most clearly when the duty cycle, cooling, and controller strategy are aligned with how the vehicle actually works.

This guide explains PMSM advantages and PMSM limitations in practical engineering terms, with an emphasis on working-class new energy vehicles like sanitation trucks, light logistics vehicles, low-speed utility vehicles, and special-purpose platforms.

Most electric vehicle drive motor discussions compare a few mainstream motor families.

PMSM (Permanent Magnet Synchronous Motor): High torque density, strong low-speed control, high efficiency potential.

Induction motor (asynchronous motor): Robust and magnet-free, but efficiency and power factor can drop more under partial load and low-speed conditions.

Other options (e.g., SRM): Can work well in specific designs, but require different trade-offs in control, noise, and torque ripple.

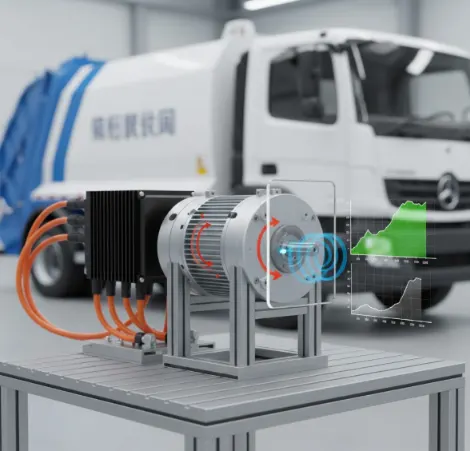

In a modern EV drivetrain, PMSM is often selected because it can combine compact packaging with controllable torque. That matters most when the vehicle spends real time below rated speed, under variable load, with frequent stop–start events.

A PMSM-based electric vehicle drive motor can often achieve high power density because the rotor’s magnetic field is provided by permanent magnets rather than rotor excitation current. In practical terms, higher torque density can translate to a smaller motor for a given performance target, which is valuable in compact chassis layouts, tight motor bays, or integrated e-axle designs.

For non-passenger vehicles, the “feel” of the drivetrain is dominated by launch, low-speed traction, and load pickup. PMSM is often chosen as a low speed high torque motor solution because it can deliver stable torque from low rpm with fine control. This is especially useful in:

sanitation vehicles that crawl and stop repeatedly,

logistics vehicles that launch under payload,

low-speed utility vehicles that operate near the bottom of the speed range.

In these applications, the biggest win is not top speed. It is repeatable low-speed torque without harshness, shudder, or early thermal derating.

Many EV duty profiles do not sit at one “best efficiency point.” They spend time in partial load, in mid-speed cruising, and in repeated accelerations. PMSM can maintain high efficiency and high power factor over a broader load range than many induction systems, which is one reason it is widely adopted in energy-focused designs.

For a working vehicle, this often shows up as more consistent real-world range and less “range collapse” during stop–go operation.

A PMSM does not deliver its best behavior on its own. It delivers it when control is good. With modern vector control and appropriate feedback options, PMSM supports precise torque control, smooth low-speed motion, and fast response to load changes. This is one reason PMSM is common when drivability, traction stability, and predictable launch behavior are priorities.

When you pair a PMSM electric vehicle drive motor with a realistic duty cycle and a credible cooling plan, the system can run cooler and more stably over long shifts. Lower temperature rise helps insulation life, bearing grease stability, and long-term consistency.

A strong article must say what can go wrong, because those constraints shape engineering decisions.

Most high-performance PMSM designs rely on rare earth permanent magnet materials (commonly NdFeB). That creates a real-world planning constraint: magnet cost can fluctuate, and supply conditions can vary by market and procurement timing. This does not mean PMSM is “too expensive,” but it does mean the motor BOM can be more sensitive to material pricing than magnet-free alternatives.

A PMSM rotor’s magnets can be sensitive to high temperatures. Poor cooling design, excessive sustained overload, or repeated high-current events can increase rotor temperature and raise the risk of partial demagnetization. In practice, thermal management is not a nice-to-have. It is a core part of PMSM reliability, especially in:

high ambient temperature regions,

sealed motor compartments with weak airflow,

platforms that run long shifts at high load.

This is where EV motor duty cycle becomes a design input, not a box-check. If your vehicle’s duty cycle includes long periods near continuous torque, you need to confirm temperature rise and derating behavior under that exact profile, not only at rated point tests.

PMSM is often paired with more demanding control requirements than some teams expect. You need credible inverter matching, correct motor parameters, and stable control tuning. If the inverter is not well matched, symptoms can include torque ripple, extra heat, unstable launch feel, or weaker low-speed torque than the catalog suggests.

Some teams still shortlist induction solutions when magnet cost, supply risk, or extreme thermal constraints dominate the decision. In those cases, the most useful comparison is how each system behaves under the same duty cycle and control limits—not just nameplates.

For some highly cost-sensitive platforms with very simple operation, PMSM may not always produce the best total value. If a vehicle operates in a narrow band, has low performance demands, and rarely stresses the motor thermally, a different motor choice (or a simpler implementation strategy) may compete well on cost. The point is not that PMSM is “overkill,” but that the value of PMSM depends on real use, not the label.

If your vehicle lives in stop and go operation and repeatedly launches under payload, PMSM’s low-speed controllability and torque delivery can translate into better drivability and less stress on mechanical components. This is why PMSM is common in working-class new energy vehicles that behave more like industrial machines than passenger cars.

Vehicles that climb ramps, crawl at low speed, or operate with attachments often benefit from a low speed high torque motor profile. PMSM is a strong candidate when you want torque where the vehicle spends most of its time, not only at one rated speed.

If energy cost per route, real-world range stability, or battery sizing is a core project constraint, PMSM’s strong EV motor efficiency across variable speed and load often becomes valuable. The win is usually not a single percentage point at peak efficiency. It is consistent efficiency across the duty profile.

If the platform’s performance targets are modest and the duty profile is light, the premium for magnets and integration effort may not always pay back quickly. A motor decision should always include total system cost and expected operating profile, not only “best motor technology.”

If you cannot implement credible cooling, and the duty cycle includes sustained high load, PMSM performance can be limited by thermal derating. In these cases, the engineering answer might be “fix the cooling and system layout,” not “change the motor,” but the limitation still matters during planning.

A motor does not live alone. The system does.

Before finalizing a PMSM-based electric vehicle drive motor, confirm:

the exact duty profile (starts per hour, continuous run time, grade events),

cooling method (air, liquid, enclosure airflow),

inverter current limits and control capability,

thermal derating behavior under the real route.

Rated kW is a useful filter, but it does not predict whether the vehicle will feel strong on ramps at hour eight of a shift. Whenever possible, size around measured route data and worst-case events, then verify test results against the model.

PMSM-based electric vehicle drive motor is often a strong choice because it combines torque density, low-speed controllability, and efficient operation across real working ranges. At the same time, PMSM limitations are real: magnet supply sensitivity, tighter thermal constraints, and greater dependence on good controls and integration. The best outcomes come when the motor, inverter, cooling plan, and EV motor duty cycle are treated as one system.

ENNENG (Qingdao Enneng Motor Co., Ltd.) develops and manufactures permanent magnet motor solutions, with a strong focus on low-speed, high-torque PMSM, constant-speed permanent magnet motors, and direct-drive designs across both high- and low-voltage ranges. The company emphasizes “Precision Performance,” applying modern design and manufacturing processes to deliver products aligned with recognized quality standards. On its official site, ENNENG highlights PMSM strengths such as suitability for low-speed high-torque applications, simplified drivetrains in certain setups, and energy-saving potential when paired with VFD control. Across industrial sectors like petrochemical, mining, rubber, ports, and water-related systems, ENNENG positions its motors as stable, reliable solutions that support efficiency goals and demanding operating conditions.

Q1: Is PMSM always the most efficient electric vehicle drive motor?

A: Not always at every single operating point, but PMSM often delivers strong EV motor efficiency across a wide variable-speed range when the system is well matched.

Q2: What are the main PMSM limitations in EV applications?

A: Key PMSM limitations include reliance on rare-earth magnets, thermal sensitivity that raises demagnetization risk under poor cooling, and higher integration demands for control and inverter tuning.

Q3: Why is PMSM common in stop–go working vehicles?

A: Because PMSM can deliver stable low-speed torque and smooth control during frequent launch and braking events, which is typical in sanitation and logistics duty.

Q4: How does EV motor duty cycle affect PMSM reliability?

A: A heavy duty cycle increases heat and stress. If the motor repeatedly runs near continuous torque without adequate cooling, thermal derating and long-term reliability risks rise. Duty cycle should be validated against temperature rise, not just rated power.

Q5: When should you consider an induction motor instead?

A: If magnets are a supply constraint, the platform is extremely cost-sensitive, or the operating profile is narrow and light, induction options may compete well. The right choice depends on system goals, not a one-size rule.