High-efficiency air systems increasingly pair variable-frequency drives with permanent-magnet synchronous motors. You get tight speed control, strong low-speed torque, and lower electrical losses in most duty cycles. Yet the hidden conversation usually surfaces later: maintenance. This article lays out where the maintenance burden really shows up, how those issues differ from induction machines, and what you can do to keep uptime steady without ballooning spend.

Compared with induction machines, a PMSM uses permanent magnets in the rotor and runs at synchronous speed. That design removes rotor copper loss and cuts heat at the source. In air compressors, that translates into good part-load behavior, fewer wasted kilowatt-hours during pressure tracking, and quieter rooms. Still, the control stack gets more delicate, and service actions shift from pure mechanical work to electro-mechanical checks plus drive tuning.

A PMSM rotor carries magnets (NdFeB or similar), so it needs no magnetizing current. Efficiency and power factor stay high from roughly 20% to 120% load, which suits compressors that rarely sit at one fixed point. Induction motors draw magnetizing current and drop off in efficiency when the load swings, which is common in plants with fluctuating air demand.

Even with better electrical efficiency, heat, vibration, and alignment still decide life. The inverter, encoder or sensors, and cable terminations are now part of the “motor system.” Small faults—poor shielding, loose lugs, or a fan that lost flow—can nudge magnets toward risk or push bearings into fatigue sooner than expected.

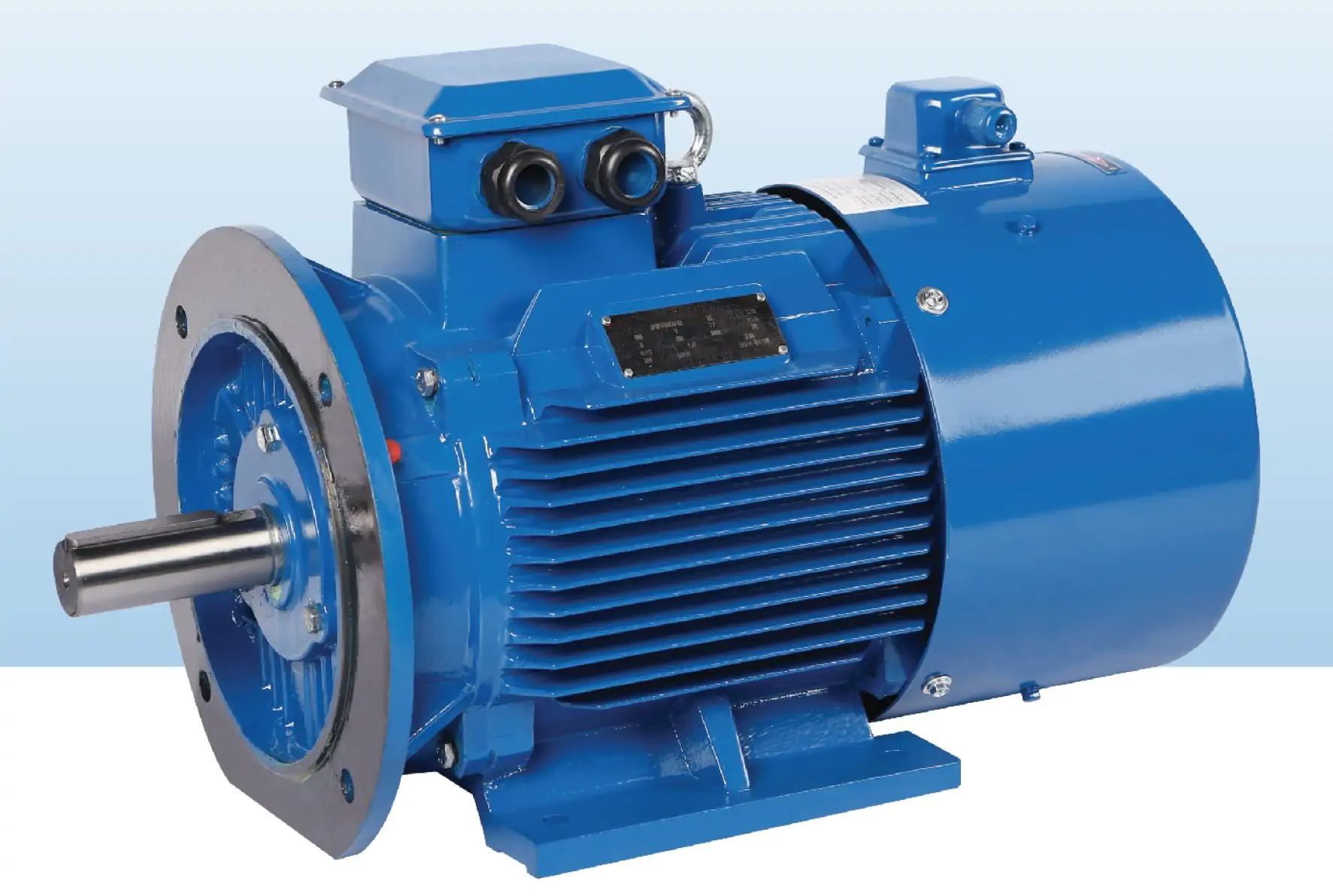

In air-compressor duty, a permanent-magnet variable-frequency motor like this one is designed for a temperature rise below about 60 K and high efficiency over a wide speed range; your job in maintenance is to keep those built-in advantages intact, not to add extra complexity. Treat the motor, VFD, and cooling path as one system: keep airflow and filters clean, follow a fixed bearing inspection and regrease interval, and lock in a soft-start, vector-control setup with a known-good parameter file. During commissioning, record baseline stator temperature, vibration, and input power at a few key pressure points, then use those values as reference trends in later checks. With that data-driven routine, PMSM-driven compressors can sustain IE4-level efficiency, stable pressure control, and long service life while keeping day-to-day maintenance effort similar to, or lower than, a conventional induction-motor system.

Energy savings take center stage, but availability and end-of-life matter when you operate fleets across many sites. Treat these as cost and risk items, not afterthoughts.

PMSM rotors depend on rare-earth materials. Pricing shifts and long lead times can affect spare-part plans. If your air demand is mission-critical, keep one “hot spare” in the building or a vendor-guaranteed swap on contract.

Damaged rotors aren’t as simple to recycle as steel stacks. Coordinate with a qualified recycler who handles magnet deactivation and safe transport. It’s not glamorous work, but it avoids unpleasant surprises with compliance and fees.

You can keep the benefits and cut the pain with a few habits. These are simple, repeatable, and friendly to teams that already track compressors.

Specify magnet grades for your ambient and duty class, not only headline power. If the room bakes in summer, choose higher-temperature grades and verify cooling routes. PMSM options with modular end-bells and easy-access bearings reduce mean time to repair. On compressor-specific motors, a temperature rise below roughly 60 K supports longer life at similar load, and IE4-class efficiency helps hold heat down.

Set alerts for stator temperature and overall vibration; trend, don’t guess. Add an annual demagnetization check during the shutdown season. Calibrate sensors each time you open the drive. If you use predictive tools, start with temperature and vibration on the motor and cooling fans before you expand to everything else.

Give technicians a short drive-parameter playbook: motor ID, current limits, speed limits, and the exact encoder or sensor model. Keep one known-good parameter set per model on a USB stick and on your server. When you plan lifecycle cost, include the potential premium for rare-earth rotor parts and compare it with energy savings from IE4-level motors. In many plants, the energy side wins by a wide margin, but you still need spare coverage. For context, PMSM systems in industrial applications often report 5%–30% system energy savings versus comparable induction setups, while power factor can reach about 0.95 or higher.

Induction motors keep maintenance simple: bearings, fans, and basic electrical tests. PMSMs shift the mix. You may spend less time on grease and more time on diagnostics, firmware, and parameter checks. Replacement parts differ too; a PMSM rotor is pricier than a standard squirrel-cage. Balance that with lower electricity spend and cooler running. If your room cycles a lot, PMSM efficiency at light load can be a direct line to lower bills. To evaluate fairly, read your utility data, not only nameplates.

If you want a quick technical deep dive aligned to your compressor use case—duty cycle, target pressure band, ambient heat—review the product detail for this pmsm motor advantages and disadvantages and map it to your site’s real run profile. Placeholders don’t pay bills; your load curves do.

When you need to spec or replace a permanent magnet motor for air compressor service, check the rated efficiency class, temperature rise, and available cooling methods first. Those three items tell you a lot about life and maintenance pace.

Qingdao Enneng Motor Co., Ltd. focuses on the R&D and manufacturing of permanent-magnet motors for industrial service. The portfolio spans low-speed high-torque, constant-speed, and direct-drive designs across multiple cooling types. Products follow IEC installation dimensions and GB30253 efficiency grades, with options such as encoders, PTC/PT100 sensors, and IP54 or higher protection. In compressor duty, you’ll see highlights like IE4-level efficiency, high power factor, and temperature rise targets suited for long runs. The company reports wide industrial use in sectors such as mining, rubber processing, water treatment, and conveying systems, paired with variable-frequency vector control for precise torque at low speed. If you need tailored parameters—frame size, voltage class up to medium voltage, or specific cooling—custom builds are available so you can match performance to the room’s pressure control and downtime needs.

Q1: How Often Should You Schedule PMSM Motor Maintenance?

A: For compressor rooms with daily cycling, plan quarterly vibration checks, semi-annual thermal scans, and an annual parameter audit on the drive and sensors.

Q2: What Are Early Signs of Demagnetization?

A: Rising stator current at the same pressure setpoint, more heat at equal load, and poor torque at low speed. Confirm with temperature history and a demag test before replacing parts.

Q3: Which Bearings Work Best for PMSM Compressor Duty?

A: Use bearings sized for your axial and radial loads, with grease compatible with ambient temperature and any oil mist. Stick to a fixed regrease schedule and trend vibration.

Q4: What Drive Parameters Matter Most After Service?

A: Motor ID, current and speed limits, encoder configuration, and vector control mode. Keep a known-good parameter file and a change log for traceability.

Q5: When Would an Induction Motor Be a Better Fit?

A: If spare-part availability is critical, ambient temperatures are high and hard to control, and load swings are small, an induction motor can be simpler to keep running with lower parts cost.