If you run or spec electric sanitation vehicles, you already know the hardest part is not top speed. It is the slow crawl, the constant start and stop, the full bins, and the steep ramps behind stations. In that duty, the traction motor becomes the real core of the machine. Pick the wrong type and you burn battery, fight overheating, and see trucks come back early from a shift.

Today the two main choices are permanent magnet synchronous motors (PMSM) and induction motors. On paper both can move a truck. In real city routes, with low speed and heavy stop and go, they behave very differently. This article walks through the key points so you can decide which side fits your fleet better.

Sanitation vehicles rarely cruise at a steady 60 km/h. Most of the time they sit in the 0–20 km/h band, creeping, braking, and collecting. That pattern is tough on any traction motor.

Every start needs high torque. Every brake and restart cycle adds heat. If the motor stays in low speed most of the night, it spends long hours away from its sweet spot. That is where the choice between PMSM and induction really starts to matter.

On a loaded sweeper or garbage truck, you are pushing vehicle weight, tools, and a full body. Climbing a short ramp into a transfer station can feel like a hill climb. Motors in the 10–40 kW range for sanitation duty are often rated at 1500 rpm with continuous torque from 64 N·m up to 255 N·m, and peak torque far higher for short bursts.

PMSM drives tend to give strong torque from zero speed because the rotor field comes from magnets, not induced current. Induction motors need slip to build rotor current, so they usually require higher stator current and still deliver less torque density in that slow region.

In start stop duty, losses add up. Induction motors carry rotor copper losses all the time. PMSM types remove that loss path by using magnets in the rotor. Over a full shift, that can mean a few to more than ten percent less energy for the same route, which is not small when you multiply by a fleet and a year.

PMSM drives are common in many high efficiency systems because they combine strong torque, compact size, and good part load behavior. In sanitation vehicles, those traits show up clearly in stop and go work.

Because the rotor carries permanent magnets, a PMSM can deliver high torque right from standstill without a big slip region. That helps when your truck has to restart often with a full load or hold creep speed on a slope. It also lets you use a smaller frame than an equivalent induction machine, which can make packaging around axles and frames a bit easier.

Tests and field data from many sectors show PMSM efficiency gains of about 4–7 percentage points over comparable induction motors. That gap can widen at light and mid load. In sanitation routes where the truck spends hours at partial load and low speed, those small gains turn into visible extra range and less time at the charger.

Less loss means less heat in the rotor and stator. Lower temperature rise helps the life of insulation and bearings, especially in vehicles that run long night shifts in tight city streets. For the maintenance team that can show up as fewer hot smell complaints, fewer deratings, and longer grease intervals on the drive end.

PMSM is not magic. Magnets can lose part of their strength if pushed to extreme temperature or heavy fault conditions. The drive needs vector control and a suitable model of the motor. That makes control electronics and parameter setup more important than with a simple fixed speed induction motor. Cost per kilowatt is also higher at purchase, even if energy use is lower over life.

Induction motors have been the workhorse of industry for decades. They are simple, robust, and familiar. In some light vehicles and older platforms, they still sit at the heart of the drive.

For tight budgets, induction motors can appeal. They use no rare earth magnets and the technology is well known. Many workshops can rewind or service them. In moderate duty, with less start stop and lower torque demand, they can give acceptable life at low cost.

The challenge comes when you ask an induction motor to live in low speed, high torque work all day. You need more current to get the same torque as a PMSM, and you still carry slip and rotor losses. That hurts efficiency right where a sanitation truck spends most of its time. On grades, you may feel softer pull from a stop, which drivers notice.

Because they carry extra losses in the rotor cage, induction motors typically top out near 90–93% efficiency, where PMSM units can push above 95–97% in many ratings. In a plant fan that might not matter as much. In a truck that must finish a specific route on one charge, that difference can decide whether you complete the run or need a mid shift charge.

When you map all of this onto an actual electric sanitation vehicle, a clear pattern shows up.

For full bin launches and ramp climbs, PMSM drives give stronger initial push at lower current. That keeps cable and fuse sizes reasonable and cuts stress on the battery. Induction motors can do the job, but often with more current and more heat, especially if you have many short hops.

If a PMSM saves even 8–10% energy across a mixed route, that can translate into dozens of extra minutes of drive time at the end of a shift. Studies in traction and industrial drives back up that kind of advantage. Over months, this can also allow you to shrink battery size for the same route, or keep battery size and gain a comfort margin.

With better efficiency and lower rotor losses, PMSM designs usually run cooler. Cooler motors place less stress on insulation systems and bearings. Your technicians still need to watch seals, cooling, and vibration, but they have fewer overheated drive complaints. Induction drives tend to be tougher in abuse, yet in this specific duty they may reach thermal limits more often.

There are still cases where you might stick with induction. If the vehicle is a light duty unit, maybe a small support cart that does not haul heavy loads or climb long grades, the lower upfront cost can outweigh the energy savings. If you already have a stock of spare induction motors and matching drives, and routes are short, induction can still be workable.

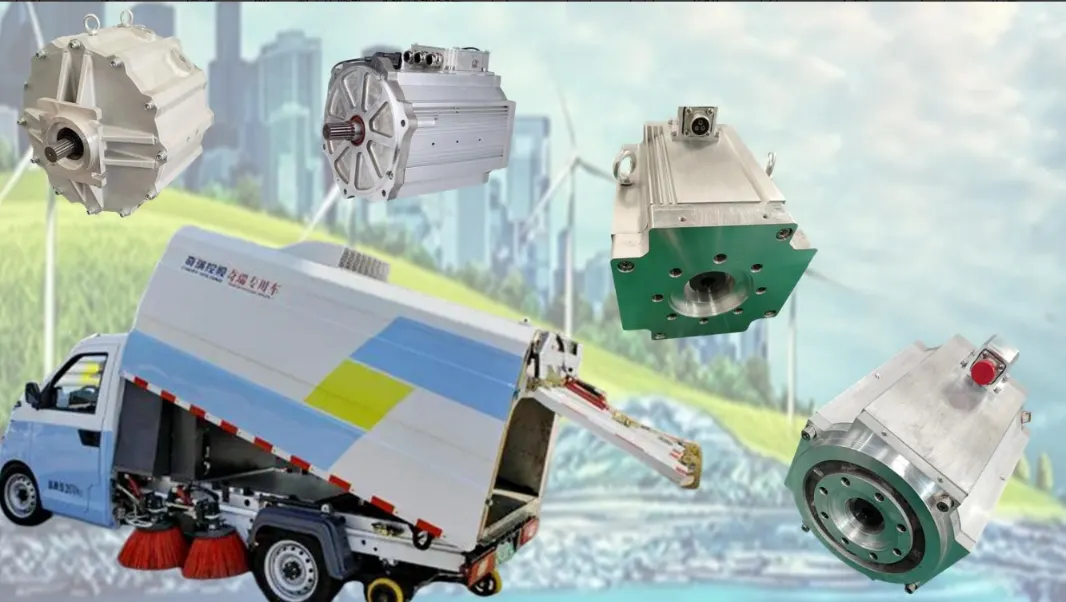

For anything you plan to keep many years in heavy city cleaning routes, PMSM usually gives you more margin on torque, temperature, and energy. That is one reason you see many 5–40 kW sanitation drive ranges built as PMSM motor series rather than as pure induction lines.

If your key routes involve heavy stop and go, frequent grades, and long shifts, PMSM is generally the more suitable choice. It gives higher torque density, better low speed efficiency, and cooler running in exactly the conditions that strain sanitation trucks. Induction motors still have a place, but more often in lighter service or where energy cost is less critical than initial price.

Qingdao Enneng Motor Co., Ltd. (ENNENG) focuses on the research and manufacture of permanent magnet motors for industrial use. The company develops low speed high torque designs, constant speed drives, and direct drive systems across high and low voltage ratings. These motors are applied in sectors such as gold mines, coal mines, tire factories, oil fields, and water treatment plants

With patented PMSM motor technology and a mix of standard and tailor made products, the company supplies electric drive motors that support low speed high torque work, wide speed ranges, and high power factors in many continuous duty applications. For operators who want to move from traditional induction drives to high efficiency solution, ENNENG offers practical paths to cut losses while keeping retrofits manageable.

Q1: Why is stop and go duty so hard on induction motors in sanitation vehicles?

A: Induction motors need slip and rotor current to make torque. In low speed work that means higher losses and more heat, especially when the truck starts and stops all the time with a heavy load.

Q2: Does a PMSM always save energy compared with an induction motor?

A: In most sanitation duty cycles, yes. PMSM drives cut rotor losses and often reach a few to several percentage points higher efficiency, which adds up over long shifts and many vehicles.

Q3: Are PMSM motors harder to control than induction motors?

A: The drive needs proper vector control and motor data, but modern inverters handle that well. Once set up, daily use is no more complex for the operator than with an induction system.

Q4: What power range makes sense for electric sanitation vehicles?

A: Many small and mid size electric sanitation vehicles use motors in roughly the 5–40 kW range, with torque sized for full load starts and short slope climbs rather than high top speed.

Q5: Can you mix PMSM and induction motors in the same fleet?

A: You can. Some operators keep induction motors on older or light duty units and shift new or high demand routes to PMSM. That way you gain energy savings and better drive behavior where they matter most, without scrapping everything at once.