Why Permanent Magnet Generators Are Replacing Traditional Generators in Wind and Water Power Applications

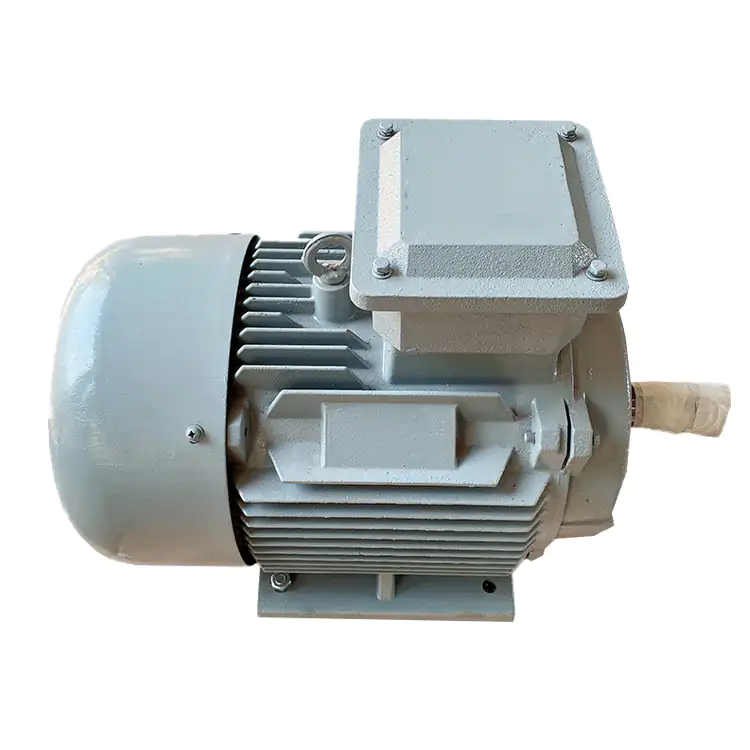

img.PMSG suitable for wind power and water power1.webp

If you work with wind or water power equipment for a while, you start to notice a pattern: once a line tries a high-efficiency generator, it rarely goes back. In many projects, that “next step up” is a permanent magnet solution. The question is not just why the change is happening, but what it means for your own systems, costs, and long-term reliability.

For wind and water power applications, generators see low speeds, changing loads, high humidity, and long continuous duty. Traditional induction generators (or synchronous generators with separate excitation) can do the job, but they lose energy in the rotor, run hotter, and need more current and more components to reach the same power output.

A modern permanent magnet generator takes a different path: it uses magnets in the rotor instead of relying on induced currents or separate excitation, which improves efficiency and torque density, especially at low speeds. For wind turbines and small hydro units, that means better energy capture from the same resource and more stable output in real-world operating conditions.

From the outside, the case might seem alike. But inside, the build is not the same. In a usual induction generator, the stator makes a spinning magnetic field. The rotor follows it. This causes slip and added wastes. In a synchronous generator with separate power, the rotor needs DC flow. That brings brushes, slip rings, or a power system.

In a permanent magnet synchronous generator (PMSG), the rotor field comes from magnets. So the rotor spins in step with the stator field without power flow. This is why a good permanent magnet generator can hit levels above 90% in how well it works. It cuts iron and copper wastes compared to a standard induction machine or a usual synchronous one with power.

These build changes are not just thoughts. They truly change how much twist you get at slow speeds. They affect how even the output is over a big speed range. And they influence how hot the generator becomes in steady work. For wind and water power, where gear is often distant or tough to reach, less waste and cooler temps mean fewer halts. And less time fixing sudden breaks.

In real terms, the main differences you care about are these.

For wind and water power machines, these points lead to a generator that runs cooler. It wastes less power as heat. And it still gives strong twist at low speed.

Wind systems, especially small and medium turbines, rarely sit in ideal, constant conditions. Wind speed changes, the mechanical torque from the rotor varies, and the electrical side has to react without wasting energy. A high-efficiency wind power generator built on permanent magnet technology helps you capture more energy in the same wind resource.

Many wind rotors turn slowly. To get usable power at those speeds with a traditional generator, you either oversize the machine, add a high-ratio gearbox, or accept higher losses. Permanent magnet generators handle low-speed, high-torque operation well, which is why they are widely used in direct-drive and medium-speed wind turbines.

For you, that means better use of low and medium wind periods, not just peak gusts. Even when wind speed drops, the generator can still deliver effective output instead of falling into an inefficient operating zone.

Studies and field data often show permanent magnet designs gaining 5–10 percentage points in efficiency over comparable induction or separately excited synchronous generators in variable load applications. Over thousands of running hours, that difference becomes real money, especially where electricity prices are rising or where projects must hit strict energy performance targets.

img.PMSG suitable for wind power and water power2.webp

Water power brings another set of challenges. Generators are driven by turbines or hydraulic transmissions in damp, sometimes spray-rich environments. You want stable torque conversion, reliable sealing structures, and a machine that does not waste power as heat.

In many small hydro and water-related generation projects, permanent magnet generators have shown lower power consumption on the mechanical side and better part-load efficiency, which matters when the system rarely runs at full design flow or head. A well-matched generator can keep output stable even when flow or head changes across the day or seasons.

Water-related generation systems often run around the clock. Here, extra losses become extra heat, which shortens insulation life and stresses bearings. By cutting excitation losses and reducing rotor heating, a permanent magnet generator can handle long duty cycles with less temperature rise.

Over time, that supports longer service intervals and more predictable downtime planning. You spend less time worrying about hot spots, insulation aging, and repeated rewinds, and more time delivering stable power to the grid or local load.

You do pay more at the start for a permanent magnet solution. Magnets and control systems add cost. But if you look at total cost over several years, the picture shifts.

Many users see payback in one to three years in continuous or near-continuous service, especially in pumping-storage, run-of-river, or small hydro and distributed wind projects.

To make the differences easier to read at a glance, you can compare permanent magnet generators and traditional generators in wind and water power setups like this:

The other side is non-financial. When the generator runs with fewer unexpected stops, you gain schedule stability, smoother operation for connected equipment, and fewer emergency site visits in bad weather or remote locations. That is hard to put into a neat formula but very real in daily work.

When you select a permanent magnet generator for wind or water duty, you look beyond nameplate power rating. Key points include required torque at low speed, expected speed range, ambient conditions, cooling method, and how the generator will be connected to the grid or local load. Matching the turbine, gearbox (if any), converter, and generator as a package is often more important than any single spec.

In both cases, clear duty data from your side makes it easier to get a design that works smoothly instead of “just barely fits”. The more precise your information on speed range, torque, environment, and expected lifetime, the better the supplier can match the generator to your real project needs.

ENNENG (Qingdao Enneng Motor Co., Ltd.) focuses on designing and manufacturing permanent magnet AC machines for industrial and energy applications. Its product range includes low-speed high-torque machines, constant-speed permanent magnet units, and direct-drive solutions that can work as generators in projects such as mines, water treatment, and renewable power equipment.

ENNENG adopts high-efficiency NdFeB magnets and rotor structures that reduce iron loss and stray loss, helping its permanent magnet machines reach efficiency levels that can be 5–10% higher than comparable induction or conventionally excited models.

Q1: Are permanent magnet generators always better than traditional generators?

A: Not in every case, but in wind and water power applications with long running hours and low speeds, the efficiency and torque advantages are usually very clear. For short-duty or very low-cost projects, traditional solutions may still be acceptable.

Q2: Do permanent magnet generators need special converters or controllers?

A: Yes. They are normally paired with modern frequency converters or dedicated grid-tied controllers. The good news is that most industrial drive and inverter suppliers support this type of machine today, especially in wind and small hydro segments.

Q3: Is the higher purchase price worth it for small projects?

A: For short-run or occasional-use systems, the payback is slower. For generators that run many hours per year, energy yield improvements and lower maintenance often justify the extra cost within a few years.

Q4: Can an existing induction generator system be upgraded to a permanent magnet generator?

A: In many cases it can, but you need to review mounting, speed, torque, the turbine side, and the electrical interface so the new generator matches both the mechanical and electrical setup. A converter upgrade is often part of the package.

Q5: What matters most when choosing a permanent magnet generator for wind or water equipment?

A: Clear data on mechanical torque, speed range, and environment. With that, you and the supplier can match torque, protection level, cooling, and duty cycle to get a generator that runs steadily rather than just meeting a catalog value.