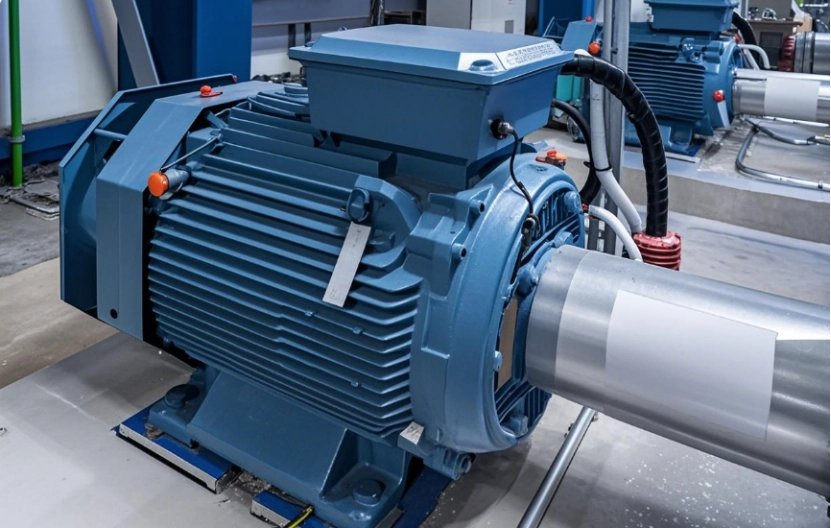

Permanent magnet synchronous motors (PMSMs) are popular in today’s industries. They save energy and work reliably. But like all machines, they can have problems. One big issue is motor overload. If not checked, overload can cause serious harm, shorten motor life, and halt your work. This guide explains the causes of motor overload, how to check and calculate it, and ways to protect your motor. Whether you’re new to motors or a factory worker, this guide is easy and useful for all.

Knowing the causes of motor overload is the first step to avoid damage. In PMSMs, overload happens when the motor works harder than it’s built for. This can come from mechanical or electrical issues.

On the mechanical side, too much force from connected machines can stress the motor. If the equipment it’s linked to is stuck or not aligned right, the motor works harder. This can lead to overload. Worn bearings also add resistance, which increases the load.

On the electrical side, problems like uneven voltage or shaky power supply can make the motor pull too much current. This creates heat and wears out parts faster.

ENNENG, a trusted maker of PMSMs, uses careful design to reduce overload risks. Their motors are made to handle tough tasks without failing, perfect for hard settings like factories and mines.

Finding overload early is key. Overload can cause overheating. This damages insulation and weakens magnets in PMSMs—a problem called demagnetization. It also lowers efficiency, wasting more energy.

At ENNENG, their “Precision Performance” approach builds motors that stay efficient and strong, even under stress. That’s why learning how to check motor overload is an important skill for anyone using these machines.

You don’t need to be a pro to check for motor overload. A few tools and steps make it simple. First, use thermal imaging cameras to find hot spots on the motor. High heat often means overload.

Next, try vibration analysis tools. If the motor shakes a lot or makes odd sounds, there might be a mechanical issue raising the load.

Also, check the electrical current. If the current stays higher than the motor’s rated value for a long time, it’s likely overloaded. Keeping a log of these values helps spot issues early.

One key number to track is the motor overload factor. This shows how much extra current the motor is pulling compared to what it should.

For example, if the rated current is 50A and the actual current is 60A, the motor overload factor is:

[(60 – 50) / 50] x 100 = 20% overload

This number helps you understand load conditions and plan care.

ENNENG offers motors with built-in tracking systems. These monitor current, temperature, and vibration. Such tools help users stay informed and act fast if something’s wrong.

Wondering how to calculate motor overload? Here’s an easy formula:

Overload % = [(Actual current – Rated current) / Rated current] x 100

This shows how much stress your motor is under. If the number goes past the safe range (usually 10-15%), you need to act.

By checking these numbers often, you can make wise choices about fixes or upgrades.

Here’s a real example. In the mining industry, motors face heavy and changing loads. ENNENG has made PMSMs tailored for this work. These motors handle load shifts without overheating or stopping.

Their smart systems adjust performance based on real conditions. This helps avoid motor overload fault and keeps machines running longer. It shows how vital it is to pick the right motor for your task—and how ENNENG delivers.

You might ask, do all motors need overload protection? Yes, especially for PMSMs in industrial settings. According to IEC and IEEE standards, motors must have protection systems. These prevent safety risks and machine failure.

Each industry has its own motor overload protection requirements. For instance, food factories may need fast shutdown features. Oil rigs need protection against extreme heat.

Knowing the signs of a motor overload fault saves time and money. Common signs include weird noises, heat from the motor, frequent breaker trips, and slower work.

If your PMSM acts strange, something’s wrong. Acting fast makes fixes easier.

If you spot a problem, check the motor’s alignment and load conditions first. Ensure the ventilation is clean and clear.

ENNENG offers after-sales help, including spare parts and technical support. Their team can guide you through fixing issues and suggest custom solutions to prevent future problems.

Regular care and the right tools are the best ways to avoid overload. With ENNENG’s technology and support, your motors stay steady and strong.

Email us at sales@enpmsm.com for a free consultation. Or call +86 18562780228 to talk about your project. Let’s create a solution that keeps your work efficient and stress-free!